Document Type

Article

Publication Date

12-2004

Abstract

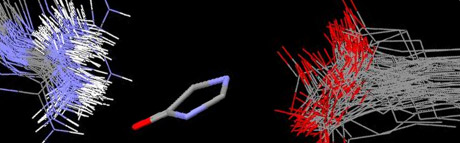

High quality manganese oxide thin films with smooth surfaces and even thicknesses have been prepared with a nonaqueous sol–gel process involving reduction of tetraethylammonium permanganate in methanol. Spin-coated films have been cast onto soft glass, quartz, and Ni foil substrates, with two coats being applied for optimum crystallization. The addition of alkali metal cations as dopants results in exclusive formation of the layered birnessite phase. By contrast, analogous reactions in bulk sol–gel reactions yield birnessite, tunneled, and spinel phases depending on the dopant cation. XRD patterns confirm the formation of well-crystallized birnessite. SEM images of Li-, Na-, and K–birnessite reveal extremely smooth films having uniform thickness of less than 0.5 μm. Thin films of Rb– and Cs–birnessite have more fractured and uneven surfaces as a result of some precipitation during the sol–gel transformation. All films consist of densely packed particles of about 0.1 μm. When tetrabutylammonium permanganate is used instead of tetraethylammonium permanganate, the sol–gel reaction yields amorphous manganese oxide as the result of diluted Mn sites in the xerogel film. Bilayer films have been prepared by casting an overcoat of K–birnessite onto an Na–birnessite film. However, Auger depth profiling indicates considerable mixing between the adjacent layers.

1

Recommended Citation

Stanton, C., Steven M., H., Timothy P., G., & Eric J., W. Manganese oxide thin films prepared by nonaqueous sol–gel processing: preferential formation of birnessite. Microporous And Mesoporous Mater., 2004, 7641-49. doi:10.1016/j.micromeso.2004.07.031

The views expressed in this paper are solely those of the author.

Comments

Initially published in Microporous Mesoporous Materials, 2004, p.41-9.

© 2004 Elsevier Inc. All rights reserved.

DOI: 10.1016/j.micromeso.2004.07.031

Final published manuscript is available at: http://dx.doi.org/10.1016/j.micromeso.2004.07.031